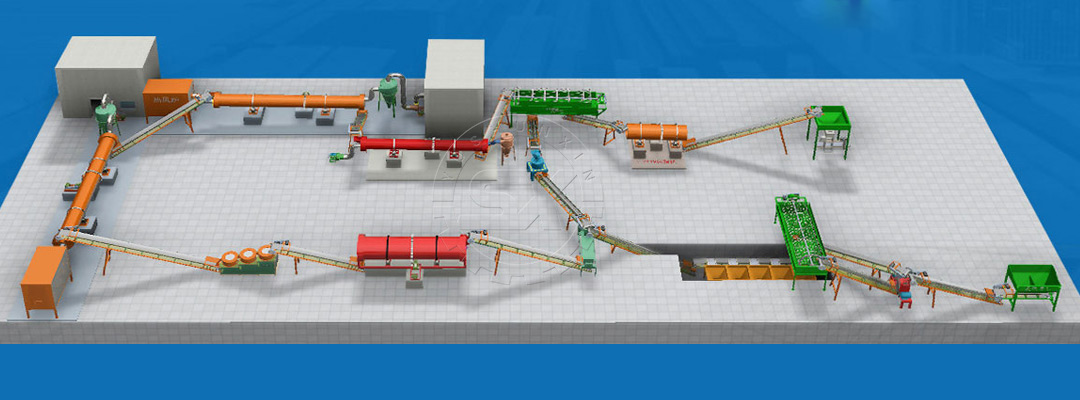

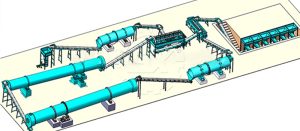

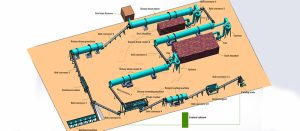

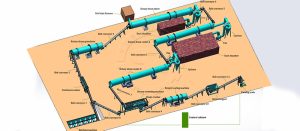

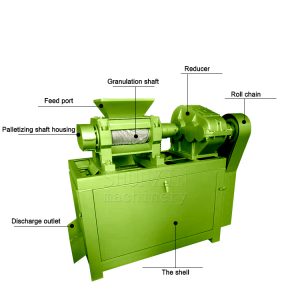

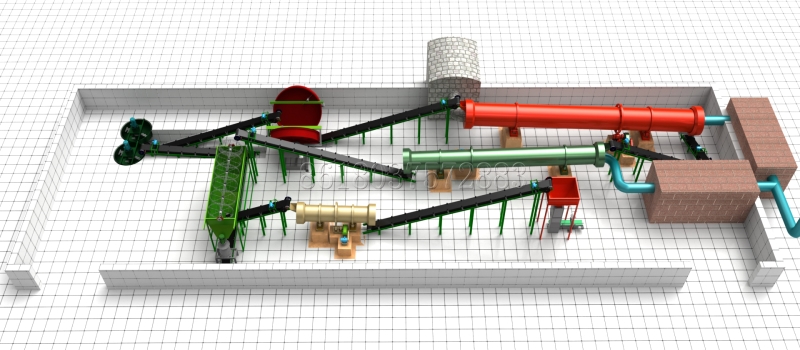

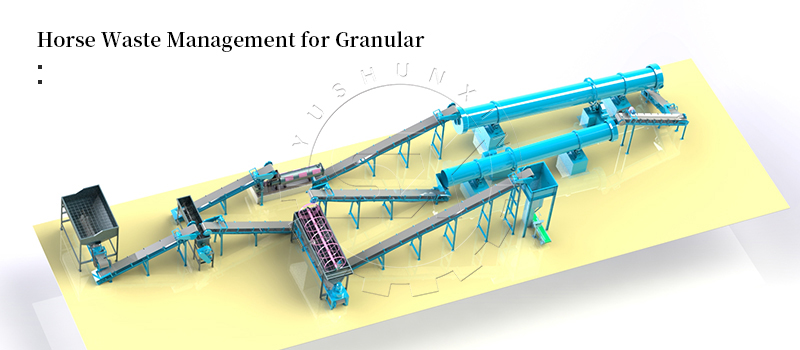

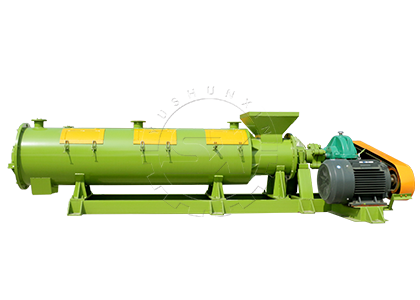

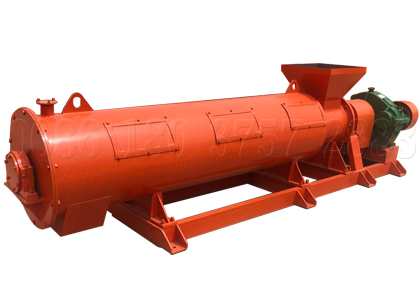

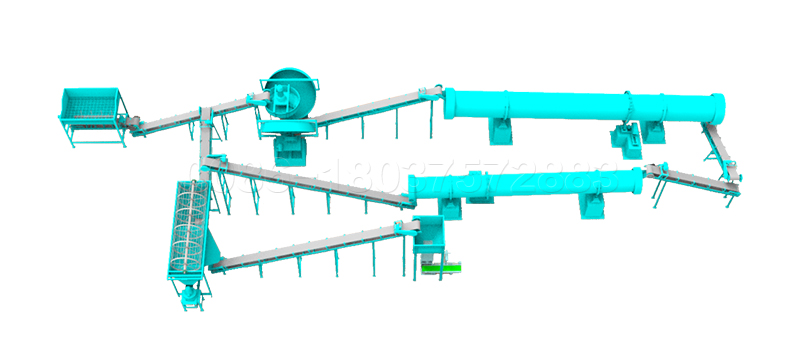

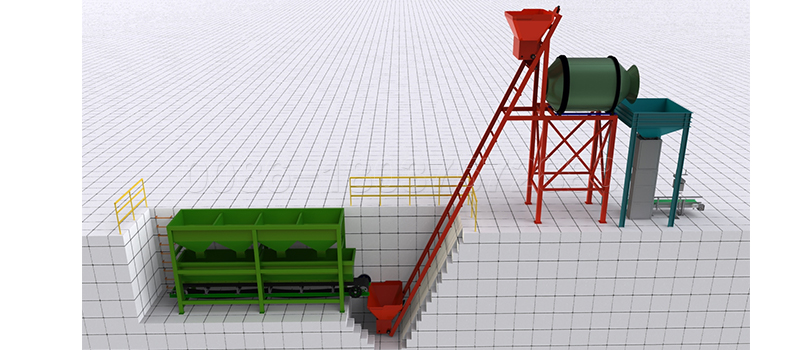

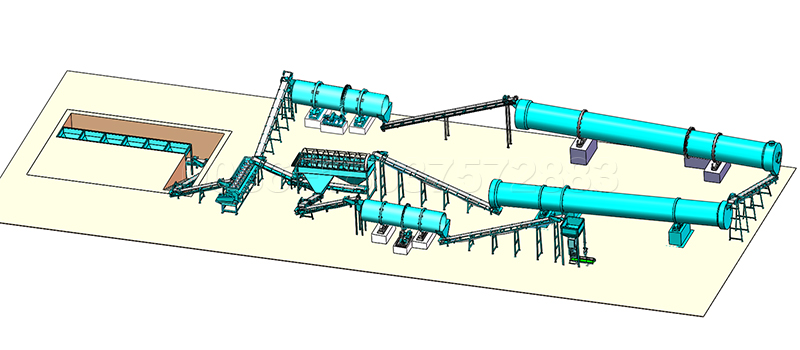

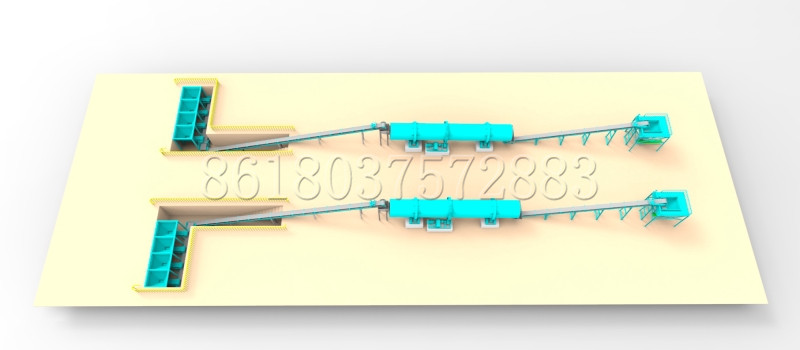

В современном сельском хозяйстве эффективное использование ресурсов и устойчивое развитие окружающей среды являются важными вопросами. При обработке навоза птицы, двухвалковая грануляторная машина для куриного помета становится идеальным выбором для многих фермеров и предприятий благодаря своим эффективным и экологичным характеристикам. Сегодня мы с гордостью представляем нашу высокоэффективную двухвалковую грануляторную машину, которая не только демонстрирует выдающуюся производительность, но и обладает экономической ценностью.

Почему стоит выбрать высокоэффективную двухвалковую грануляторную машину для куриного помета?

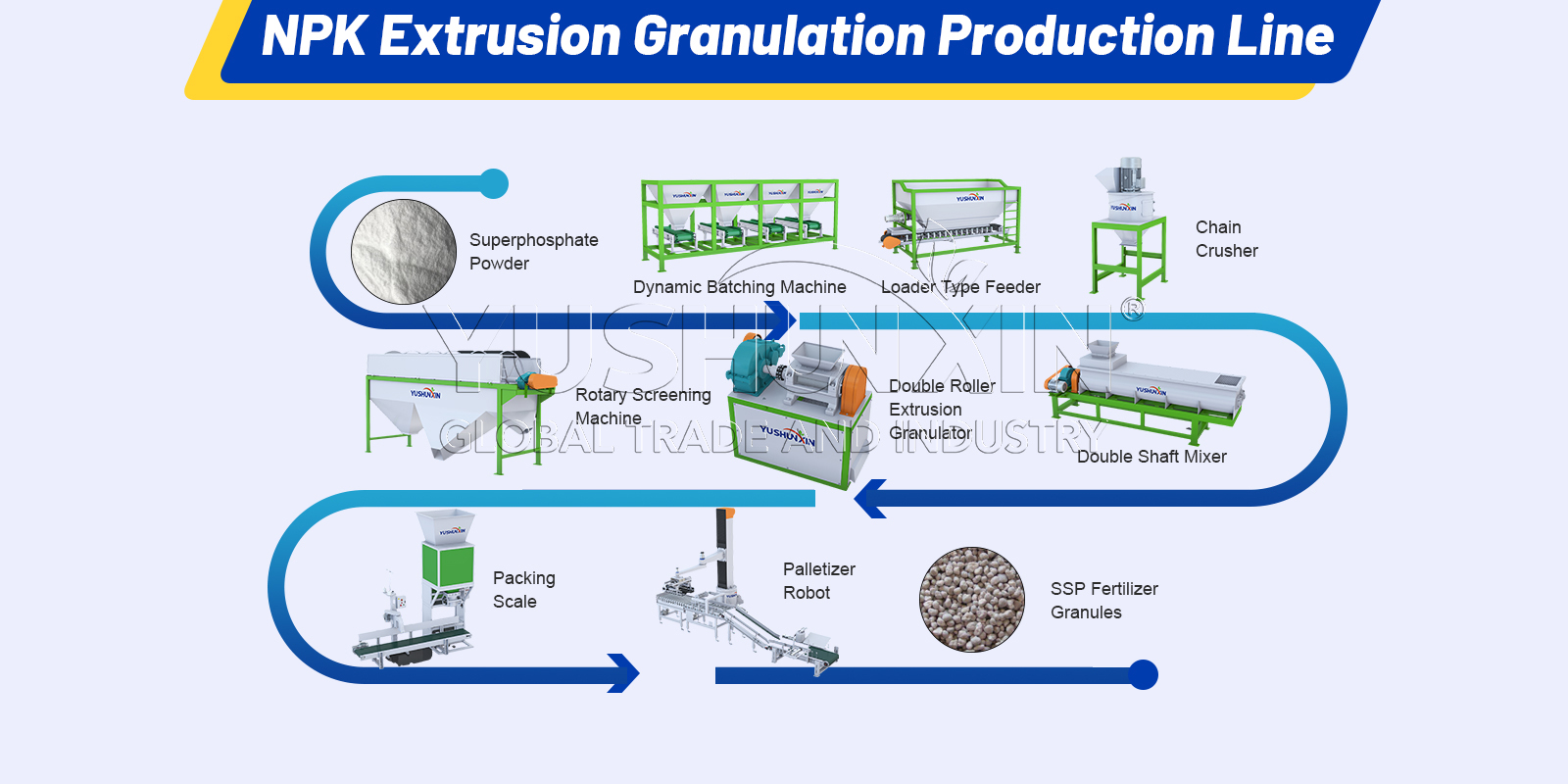

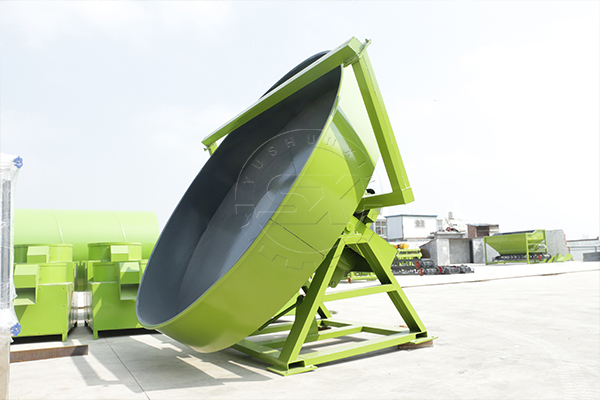

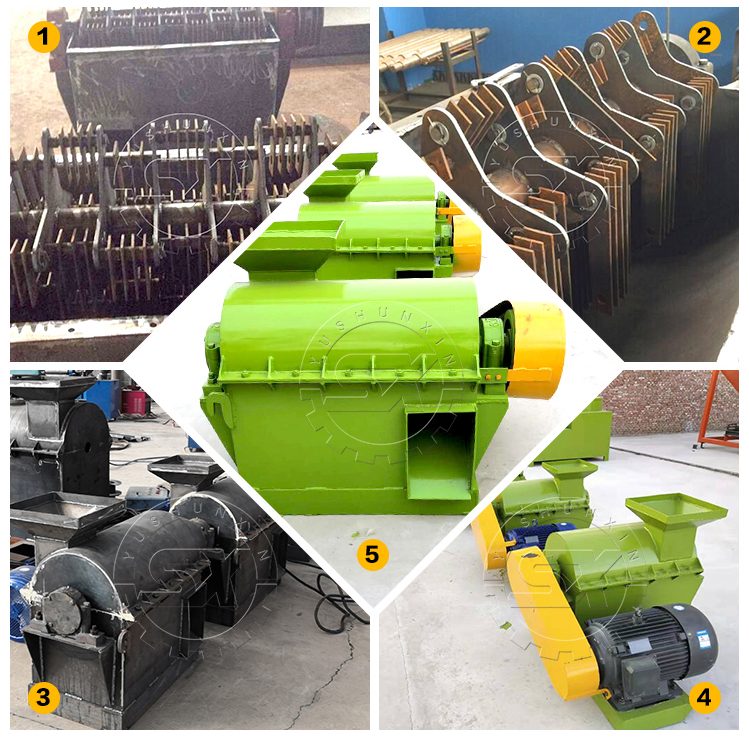

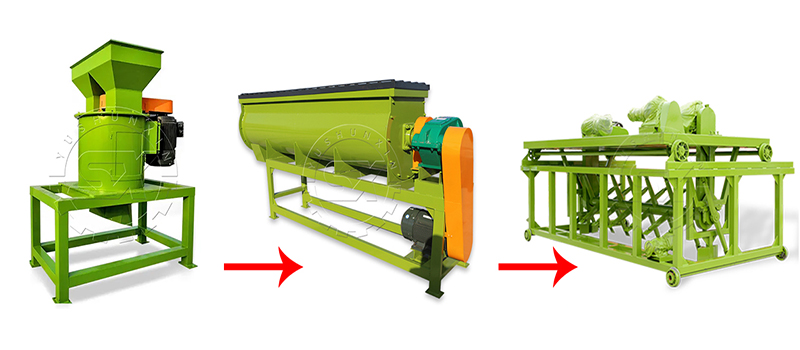

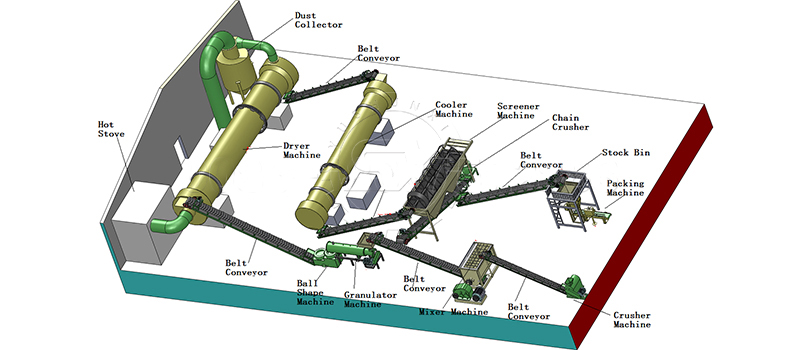

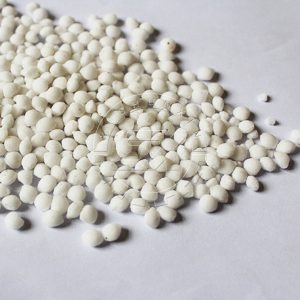

1. **Выдающаяся производительность гранулирования**: Наша машина использует инновационную технологию валковой прессовки, эффективно превращая куриный помет в равномерные гранулы, значительно улучшая физические свойства и эффективность удобрения.

2. **Энергоэффективность и экологичность**: Конструкция оборудования ориентирована на оптимизацию энергопотребления, что делает процесс работы как энергоэффективным, так и экологически безопасным, помогая пользователям сократить углеродный след.

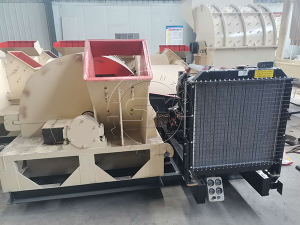

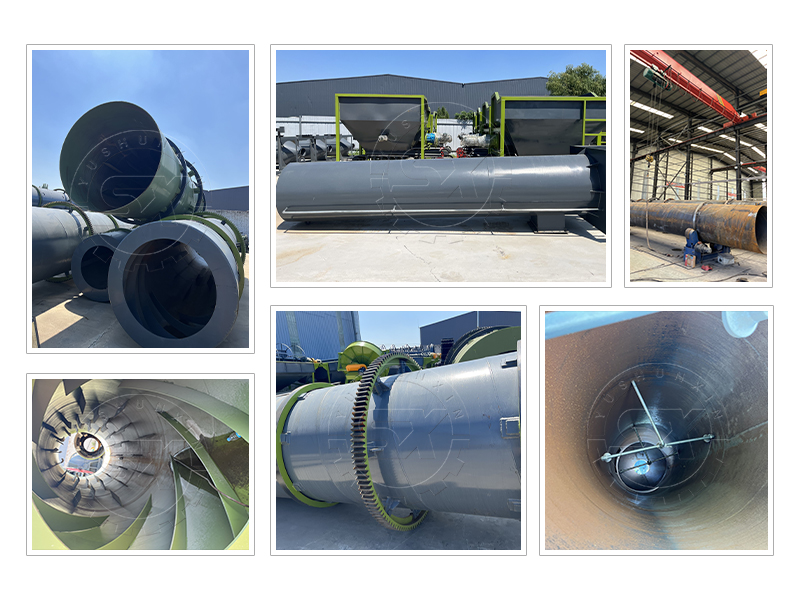

3. **Прочность и долговечность**: Изготовлена из высококачественных материалов, машина прочная и долговечная, способна выдерживать долгосрочные интенсивные производственные задачи, снижая затраты на частую замену и ремонт.

4. **Широкая адаптивность**: Наша грануляторная машина подходит для куриного помета с различной влажностью и вязкостью, что делает её универсальным решением для удовлетворения потребностей различных птицефабрик.

5. **Удобство эксплуатации и обслуживания**: Дружественный интерфейс устройства делает его простым в использовании, а продуманный дизайн обслуживания обеспечивает минимальные затраты времени и усилий для поддержания оборудования в оптимальном состоянии.

Экономическая выгода от использования высокоэффективной двухвалковой грануляторной машины

Использование этой машины позволяет фермерам и предприятиям не только эффективно перерабатывать куриный помет, но и превращать его в высокоценные органические удобрения, что увеличивает доходы от сельскохозяйственного производства. Кроме того, гранулированные удобрения легко упаковывать и транспортировать, что расширяет возможности сбыта.

Отзывы клиентов

Многие клиенты, использовавшие нашу машину, отмечают значительное повышение производительности и улучшение качества удобрений. Владелец крупной птицефабрики, господин Ли, отметил: “С введением этой высокоэффективной грануляторной машины наша производительность увеличилась на 30%, а конкурентоспособность продукции на рынке возросла”.

Покупка и обслуживание

Выбирая нас, вы получаете всестороннюю поддержку. От выбора оборудования и установки до последующего обслуживания, наша профессиональная команда всегда готова обеспечить максимальный возврат ваших инвестиций.

Высокоэффективная двухвалковая грануляторная машина для куриного помета – это мощный помощник в повышении производительности сельского хозяйства и важный инструмент для достижения устойчивого развития. Если вы хотите повысить производственные возможности с помощью инновационного оборудования, рассмотрите нашу машину. Мы всегда рады предоставить дополнительную информацию или организовать демонстрацию оборудования. Ждем вашего сотрудничества! Для получения более подробной информации посетите сайт: https://www.sxmashina.com/rolikovyy-granulyator/