In modern biofertilizer production, fermentation is the first and most critical step in transforming organic waste into nutrient-rich, pathogen-free fertilizer. While traditional composting methods rely on open-air piles or trenches, more and more producers are turning to fermentation tanks for better control, higher efficiency, and a cleaner process. But what makes fermentation tanks so valuable—and are they right for your fertilizer plant?

This blog explores the key reasons why fermentation tanks are a smart investment in professional biofertilizer production.

1. Faster Fermentation with Controlled Environment

Unlike natural composting that may take 30–60 days, fermentation tanks can complete aerobic fermentation in 5–15 days, depending on the material and system design. This is possible due to:

-

Stable temperature control (50–65°C)

-

Optimized aeration through internal blowers or mixing paddles

-

Sealed structure to maintain consistent moisture and heat

Faster cycles mean higher throughput and shorter production lead times—ideal for commercial-scale operations.

2. Safe and Sanitary Processing

Fermentation tanks offer a closed, hygienic environment, greatly reducing:

-

Odor emissions

-

Flies and pests

-

Risk of leachate pollution

More importantly, they help meet organic fertilizer safety standards, ensuring the complete elimination of pathogens and weed seeds through uniform heating.

This is essential for producers targeting certified organic markets or government-supported programs.

3. Suitable for Diverse Organic Inputs

Fermentation tanks are versatile. They handle a wide range of biofertilizer raw materials, including:

-

Livestock and poultry manure

-

Biogas digestate solids

-

Agricultural waste (straw, husks, etc.)

-

Food and kitchen waste

By adjusting the C/N ratio, moisture, and inoculants, producers can tailor fermentation recipes to their available feedstocks. Welcome to consult YUSHUNXIN !

4. Compact Footprint, Scalable Capacity

Compared to windrow composting machine, fermentation tanks require far less land, making them ideal for:

-

Urban or peri-urban facilities

-

Farms with limited space

-

Mobile or modular fertilizer plants

Plus, tank systems are available in various capacities, from 5 to 50+ cubic meters, supporting batch or continuous operation based on your production plan.

5. Ready for Integration into Production Lines

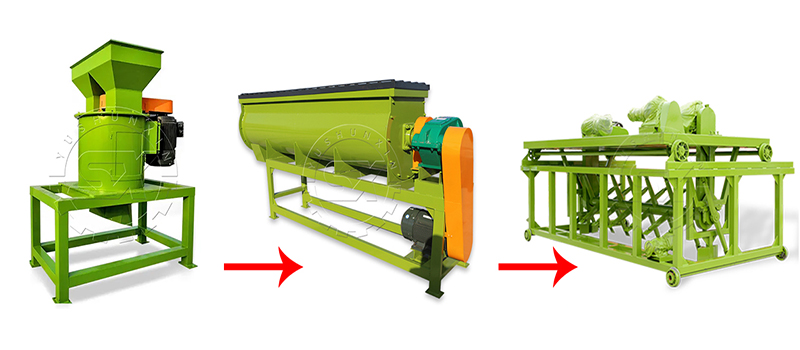

Modern fermenters are not standalone units—they integrate smoothly into complete biofertilizer lines. Whether you’re planning powder fertilizer or granulated production, the fermented material flows directly into crushing, mixing, and granulation systems. Click here to learn more about our fermentation production line.

This seamless integration:

-

Cuts labor cost

-

Boosts automation

-

Enhances product consistency

Conclusion

Fermentation tanks are more than a tool—they’re the foundation of efficient, sanitary, and scalable biofertilizer production. If you want to turn organic waste into a market-ready product faster and cleaner, investing in a fermentation tank is a smart first step. Welcome to visit : https://www.biofertilizerproduction.com/product/fermenter-for-biofertilizer-production/