In biofertilizer manufacturing, granulation plays a decisive role in determining the product’s physical quality and nutrient uniformity. Among various granulation technologies, the drum granulator, also known as a rotary drum pelletizer or drum-type granulating machine, remains one of the most reliable and widely used solutions for large-scale organic and biofertilizer plants.

Why Choose Drum Granulation for Biofertilizer Production

The rotary drum granulation process transforms fine biofertilizer powder into uniform, rounded granules through continuous rotation and controlled moisture addition. This process helps achieve consistent particle size, better storage stability, and improved spreading efficiency.

Compared with pan granulators or extrusion machines, a rotary drum granulator handles higher capacity and operates more stably, which makes it suitable for industrial-scale biofertilizer projects.

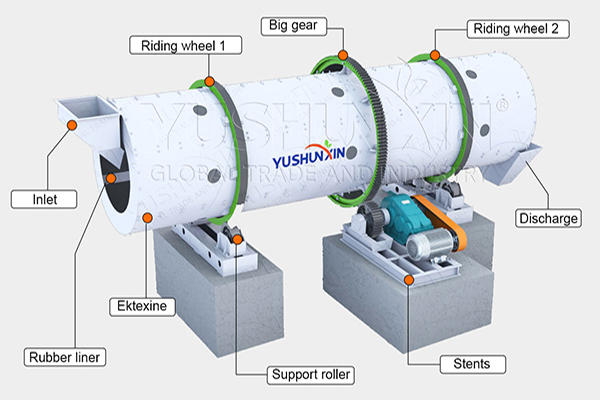

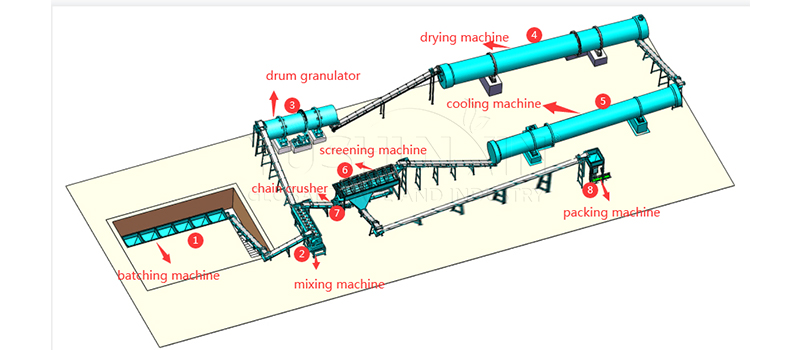

The internal structure of the drum is designed with lining plates that prevent material sticking, while the inclination angle and rotation speed can be adjusted to achieve the desired granulation rate. When paired with an automatic drying and cooling system, it forms an efficient continuous granulation line.

Applications in Modern Biofertilizer Projects

In modern production lines, drum granulation systems are often integrated into bio NPK fertilizer plants, organic-inorganic compound fertilizer systems, and microbial biofertilizer projects.

Whether the raw materials come from composted manure, crop residues, or microbial inoculants, the rotary drum pelletizer ensures even mixing and granule shaping before the drying process.

This makes it ideal for producing balanced and durable biofertilizer granules that can release nutrients gradually and promote soil microbial activity.

Key Advantages of a Drum Granulator System

High granulation efficiency: Achieves up to 90% granulation rate.

Stable and continuous operation: Suitable for both organic and compound biofertilizers.

Flexible design: Adaptable drum size, inclination, and internal structure for different raw materials.

Low maintenance cost: Simple structure, long service life.

When combined with a composting system, a drying and cooling line, and automatic packaging equipment, the drum granulation unit helps establish a complete and efficient biofertilizer production solution.

From Design to Implementation

For fertilizer manufacturers planning to upgrade their biofertilizer plants or expand capacity, choosing the right drum granulating equipment is essential. A well-designed drum granulation system not only improves the quality of biofertilizer pellets but also ensures stable operation throughout the production process. Click here to get more!

If you are considering building or optimizing a biofertilizer production project, integrating a rotary drum granulator into your process design can bring significant benefits in efficiency and product performance. Welcome to visit : https://www.biofertilizerproduction.com/product/drum-pelletizer-in-biofertilizer-production-project/