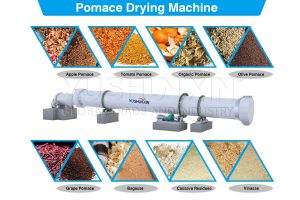

The design of a pomace drying process for fertilizer production depends heavily on the type and characteristics of raw materials. Pomace, including apple pomace, grape pomace, olive pomace, and other fruit residues, usually contains more than 80–90% moisture. Such high-moisture organic waste comes from juice factories, wineries, and food processing plants. Each industry produces pomace with different fiber, sugar, and oil contents, which influence the drying performance and the final fertilizer quality. For example, grape pomace with rich lignin and seed particles requires higher drying temperature control, while apple pomace needs uniform moisture reduction to maintain nutrient retention during fertilizer production.

When a company plans to use pomace for organic fertilizer production, it must consider both the dewatering and drying requirements. Proper dehydration improves storage stability, reduces odor, and supports later composting and granulation steps. In the fertilizer manufacturing industry, effective moisture reduction from 90% to below 10% ensures that organic particles remain suitable for forming granules and pellets. Therefore, designing a drying process involves matching the raw material composition with the specific needs of fertilizer production systems across different sectors.

How Does the Pomace Drying Machine Improve the Fertilizer Production Process?

A pomace dryer plays a central role in the entire fertilizer preparation line. This type of drying equipment controls temperature, airflow, and residence time to achieve efficient moisture reduction. During the pomace drying process, the machine transfers heat uniformly to every layer of material, preventing nutrient loss and ensuring consistent drying quality. The dryer design must consider factors such as initial moisture content, particle size, and energy efficiency. A well-engineered pomace drying system supports large-scale fertilizer manufacturing by shortening processing time and improving output stability.

In many fertilizer production procedures, the pomace dryer works together with other machines. A dewatering machine may first reduce water content mechanically from 90% to about 60%. After that, the pomace dryer further dehydrates the material to reach around 10% final moisture. After drying, composting machines and granulators or pelletizers take part in the next stages of fertilizer making. During granulation or pelletizing, uniform dryness helps produce solid particles with stable structure and easy storage. As a result, the overall process—from dewatering to drying, composting, and granulation—forms a continuous and efficient system for organic fertilizer production from pomace.

What Key Design Factors Ensure an Efficient Pomace Drying Process?

Every fertilizer producer must evaluate drying temperature, airflow design, heat source type, and control system when planning a pomace drying process. The drying temperature should remain stable to prevent overheating, which can damage organic nutrients essential for high-quality fertilizer. The airflow pattern inside the dryer affects water evaporation efficiency and uniformity of dehydration. Energy-saving heating technology also plays an important role because continuous pomace drying consumes large amounts of thermal energy.

Another factor involves the integration between the drying equipment and the entire fertilizer production line. The pomace drying machine should coordinate with upstream dewatering and downstream composting and granulation equipment. For example, when a dewatering machine efficiently removes free water before drying, the dryer consumes less energy. Similarly, when the dried pomace enters a composting or pelletizing stage with controlled moisture, the fertilizer granule quality improves. Through careful design of each step, manufacturers can establish a reliable and environmentally friendly pomace fertilizer production process that ensures consistent output and lower operational costs.

Conclusion

In summary, designing a pomace drying process for fertilizer production requires a comprehensive understanding of raw materials, moisture reduction techniques, and system integration. The main challenge lies in achieving effective dehydration while maintaining nutrient value for composting and granulation. When companies choose advanced drying machinery with precise control and high thermal efficiency, they can improve production stability and product quality. A professional drying equipment manufacturer—Yushunxin—provides specialized pomace dryer solutions, helping fertilizer producers develop efficient, sustainable, and energy-saving drying systems for various organic fertilizer manufacturing needs. You can visit: https://www.fertilizerdryer.com/pomace-drying-machine/