Carbon-based fertilizer production from chicken manure gains increasing attention due to its effectiveness and environmental benefits. The integration of advanced granulation machinery into the production process significantly improves both the efficiency and quality of carbon-based fertilizers. This blog will explore the key procedures and machinery involved in converting chicken dung into value-added powdery and granular fertilizers, focusing on how granulation plays a crucial role in the transformation.

What Raw Materials Can You Use for Carbon-Based Fertilizer Production from Chicken Manure?

The selection of raw materials directly influences the quality of carbon-based fertilizer. Chicken manure, also known as bird dung, becomes an ideal primary ingredient due to its high organic content and nutrient density. Producers often combine chicken manure with crop straw, sawdust, rice husks, or biochar to enhance the carbon content. This mixture ensures the production of powdery or granular fertilizers with balanced nutrients and organic matter.

You can also use other agricultural wastes, such as corn cobs, peanut shells, or even green waste, in the preparation process. Each type of raw material offers unique carbon sources, which, when processed together, help regulate moisture, carbon-to-nitrogen ratio, and particle size distribution. The initial processing stage usually involves crushing and mixing these raw materials to achieve a uniform powder suitable for carbonization and further granulation.

How Does Granulation Machinery Optimize Chicken Manure Carbon Fertilizer Processing?

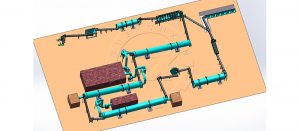

Modern granulation equipment plays a pivotal role in the transformation of chicken dung into premium carbon-based fertilizer granules. The granulation process typically follows the carbonization of powdered chicken manure. Carbonization equipment, such as a furnace, converts the mixture into high-carbon powder, which then undergoes further refining through a crushing machine or carbon fertilizer grinder.

Advanced granulators, including disc granulators, drum granulators, flat die granulators, or double roller extrusion granulators, enable the consistent shaping of powdery carbon-based materials into uniform granules or pellets. These machines allow precise control over particle size, density, and moisture content, all crucial for the stable storage, transport, and application of carbon fertilizer. The inclusion of a pelletizer or ball making machine minimizes dust, enhances granule strength, and improves nutrient release efficiency.

Additionally, the entire production line often incorporates supporting equipment, such as compost machines for pre-fermentation of chicken manure, drying machines for moisture removal, and automatic packing machines for efficient packaging. By integrating these machines, you ensure a streamlined procedure from raw material preparation through pellet making to finished fertilizer products.

What Advantages Can You Achieve from Upgraded Granulation and Production Procedures?

The adoption of specialized granulation machinery in carbon-based fertilizer production from chicken manure leads to multiple advantages. Firstly, the granulation process reduces the inherent odor and pathogens in bird manure, resulting in hygienic, easy-to-handle granules. Secondly, the resulting carbon fertilizer granules or pellets exhibit enhanced physical properties, including improved strength, uniformity, and flowability. These features contribute to easier transportation, storage, and mechanical application.

In addition, the tailored granulation procedures enable precise nutrient retention and slow-release characteristics, making the fertilizer more effective for various soil types. The use of powder to granule technology also increases the commercial value and market competitiveness of the final product, setting it apart from traditional powdered or unprocessed chicken dung fertilizers.

Conclusion

In summary, the efficient processing of chicken manure into high-quality carbon-based fertilizers relies on a comprehensive production line featuring advanced powder crushing, carbonization, and granulation machinery. This modern equipment transforms raw bird dung into standardized powdery and granulated products suitable for the fertilizer market. For those seeking a reliable partner in fertilizer equipment, Yushunxin stands out as a professional manufacturer offering complete solutions—ranging from carbonization equipment and crushing machines to specialized granulators—that elevate the production process and ensure consistent, high-value carbon-based fertilizer output. You can visit: https://www.charbasedfertilizermachine.com/product/chicken-dung-and-biochar-as-fertilizer/